Selecting the correct Water Methanol Injection System for your application

So you're looking for a WMI system for your vehicle but not sure where to start or what to select.

Here are some tips for to help make your selection easier.

First off, lets understand what Water Methanol Injection is about and how it works.

The fluids, Water and Methanol

Short off, Water Methanol Injection can be quickly described as liquid intercooling which in turn provides a safety net for moderately to extremely modified vehicles.

It can be proven further that no intercooler can cool as effectively as WMI and that the effective Octane that a system can achieve can allow owners to do away with utilizing octane boosters on pump fuel.

The principal of WMI is that is mixture of two fluids that require large amounts of heat for state change(evaporation) to occur.

The two fluids are however independent in terms of rate of change(Methanol evaporates 5 times faster than Water, but Water absorbs more heat than Methanol)

So when you are deciding on a WMI kit, you have to keep the intended(or advised) Water Methanol ratio in mind as the higher the content of either or fluid will affect the overall benefit/ effectiveness/ performance of the system once installed.

Nozzle Location

With that being said, you also have to decide where you will be injecting the Water Methanol Mix into the boost system.

It has been proven many times over that post intercooler (afterwards) injection is the most effective placement for a nozzle.

However where after the intercooler should the nozzle be placed?

Well because heat absorption occurs over a duration of time, it is best to spray as far as possible from the intake manifold to maximize heat absorption time.

So the short answer is, on the first bend of the outlet of the intercooler or on the intercooler outlet side.

Nozzle Sizing

Now this is a delicate subject, you have already been educated on how WMI works with the fluids and how much heat they absorb but how much should you inject?

Well its all got to do with heat, location and W/M ratio........Simple hey?.........Not!

This is because its all go to do with your setup on your vehicle in terms of modifications.

Small OEM stock turbo's struggle to achieve the pressures intended to operate at altitude, and this means they are spinning much faster to achieve the same boost pressure.

Because of the increased RPM, it means they are less efficient in processing air movement and therefore generate the byproduct of more heat due to inefficiencies of the turbine and compressor.

You also have to consider that if you have flashed your ECU/ Loaded it with software/ Chipped it/ Running Aftermarket Engine Management, the turbo installed is most likely too small for the higher boost pressures and because of that, it is contributing to further heat generation due to compressor effeciency.

Also we have hot days, that further more increases the heat and it just makes everything more lazy and boring, especially the performance of your car.

Also nozzle sizing is dependent on the type of fuel injection on the vehicle, Direct Injection Vehicles can run higher flow rate nozzles over Port/ Indirect Injection Fuel Injection Vehicles.

This is due to the principal of fuel combustion with Direct Injection being very different and also the heat generation during compression and combustion.

A "wet intake port" promotes "beading" of the incoming WMI due to the collision of the two fluids at the injection point.

A direct injection "dry port" does not have this issue and hugely benefits from WMI with the cleaning away of carbon deposits on the intake tract.

So I said a lot but you are still have no answer to your question.

Because its not an exact science but rather a lot of trial and error.

Ratio's of Water and Methanol Mixes

Water Aspect of WMI

Water boils at a much higher temperature being compared to the likes of Methanol, and therefore state changes slower at lower or ambient temperatures.

In the boost system, water does not play much of a role in reducing intake temperatures before reaching the combustion chambers, but does come into effect once in the combustion chambers where the latent heat is much higher.

It alters the flame front speed effectively creating octane due to its suppression of the combustion.

Too much of water will kill the motors combustion and cause a miss fire.

Higher Water content will give excessive octane and detonation suppression but will cause power loss if too much is injected.

Methanol Aspect of WMI

Methanol is considered as the instantaneous cooling aspect of a WMI System.

From the point of injection, it will rapidly state change and cool the incoming charge into the motor, increasing air density and the oxygen content, allowing for a more volumetrically efficient motor with the reduced likehood of detonation due to the altered flame front speed from the oxygen increase and change in the Air Fuel Ratio and mostly the combustion temperature.

Too much of Methanol could smother the flame front (killing a flame with fuel) and can cause excessively rich AFR's (in the 10's).

Higher Methanol content will give more cooling but less ignition advancement due to minimal suppression

Ratio's are once again a delicate subject, but you need to tackle the ratio aspect as to what issue you want to correct on the vehicle.

Static or Progressive WMI Injection

This refers to the control of the output to the pump, either it triggers on/ off or it variably injects based on the interfacing of the controller between two setpoints.

For example, between an RPM range, Boost Range, Flow Rate Range( MAF Based), etc.

Types of Controller Interfacing - MAF, Boost, TPS, RPM, etc.

Cool Boost Systems WMI controller have the ability to interface to vehicles differently based on personal preference.

Boost Based

The most popular is Boost Interfacing, but the hassle with this is that the linear delivery of WMI is only up to the settling boost.

For example, if you are spiking 1.8bar but settling on 1.2bar on redline, the ideal settings of the controller is to linearly inject until 1.2bar has been reached.

This is to prevent the system reducing injection output towards redline if set higher than 1.2bar.

Mass Air Flow (MAF) Based

MAF Based injection is the most linear and is the best type of interfacing, but the downside is that you will need to tie into your vehicles stock electronics and also find out before hand what type of MAF it is, either Voltage or Frequency based.

TPS(Throttle Position Sensor) Based

Throttle Position Sensed is most suited for Naturally Aspirated vehicles

RPM Based

Throttle Position Sensed is most suited for Carburetor Naturally Aspirated Diesel and Petrol Vehicles

Exhaust Gas Temperature Based

Suited for some Diesel vehicles during long heavy pulling up mountain passes, as soon as the EGT exceeds a settable temperature, it will activate the system and progressively spray the hotter the temperatures get.

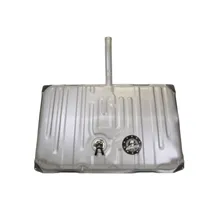

The decision on the Tank size

How long do you want to drive between fills?

Take your nozzle size in cc/min and divide it by the capacity of the tank, this will give you an estimate of the duration of system active time or foot flat driving.

How much room do have for a tank to be installed?

This comes down to personal choice, but use the above calculation as a guideline in making the decision.

Should be accessible for filling?

Remember the smaller you go, the more often you will be spending time together, so choose your bottle size according to your nozzle or it might become a pain to fill especially if it is installed in a location that requires a long tube or dismantling (such as behind a subwoofer box) to get to.

Length of Nylon Piping

Location of the tank will determine the starting point of this.

You will also have to see where you would like to route the piping during installation and where the nozzle is to be placed(end location)

A trick is to use a string to measure this all out.

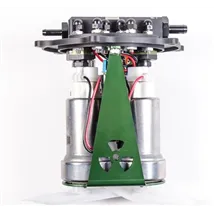

Pump and Tank Installation Locations

Engine Bay or Boot installation?

An Engine Bay installation utilizing the window washer reservoir means you will loose the functionality of washing your window.

A Boot mount installation means it will occupy space in your boot area, and that might not be ideal depending on the size of the tank.

A recommendation is to cut out a piece of wood for the boot, and install the system on to it so that you can remove the entire setup when needed, such as going on holiday.

Once the system is installed

So you have the system installed, so what Water Methanol ratio do you start with and how do you set up the controller for optimal performance for your vehicle?

I advise most to start off with a 1/1 ratio in volume (1 Liter/ 1 Liter) and to adjust the controller to activate at half the vehicles settling boost pressure(i.e. settling pressure = 1.2Bar, set the WMI activation at 0.6Bar) and set the Peak(if progressive) to the settling pressure of the vehicle (i.e. settling pressure = 1.2Bar).

Go for a drive and if the car feels uneasy on activation, immediately throw in another liter of 100% methanol, and drive it again.

If it still feels uneasy adjust the controller to activate at a later boost pressure of say 0.2-0.3bar later that than the current activation point (i.e. 0.6Bar + 0.2Bar = 0.8Bar) and go for a drive again.

If the vehicle is still uneasy, chuck in another liter of 100% Methanol and continue as above until the vehicle pulls clean through the rev range with no spluttering or bogging on Activation to Peak.

If the vehicle does not come right then its one of a few possibilities such as:

- The nozzle is wrongly placed (too close to the intake manifold)

- Nozzle Size is too large for location, flow rate, pressure or latent heat generation of the turbo

- Problem with the system (atomisation) due to pressure (possible kink in the line)